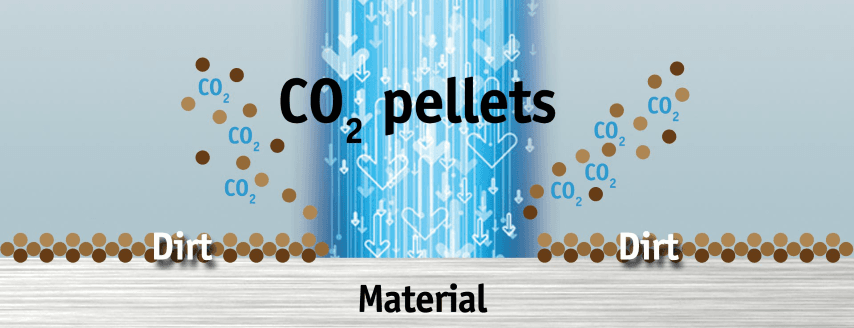

The process looks a lot like the pressure washer you’d use to clean your car or rinse down your driveway, But dry ice cleaning cleans using solid carbon dioxide (CO2) as the cleaning abrasive, compressed air stream of grain-size pellets (CO2) fired from a spray nozzle. Dry ice cleaning does not use water or aggressive media like sand or glass.

The Blasting lab has spared no expense for our equipment using state-of-the-art, pattened technology equipment that cost a lot! Our Dry Ice cleaning is designed to give the user complete control. Utilizing Cold Jet’s patented Particle Control System™ (PCS), dry ice is cut dry ice into diamond-shaped particles in the exact dimensions chosen by the operator (0.3mm to 3mm and every size in between), allowing the user to fine-tune cleaning parameters for each unique application.

Abrasive blasting. Unlike dry ice blasting, abrasive blasting is highly toxic and dangerous for the operator. The operator must wear a protective suit with a self-contained breathing apparatus to avoid exposure to the fumes and dust created during blasting.

Soda blasting. This is a variation of abrasive blasting with the same positive toxic, environmental and conductive qualities, but still abrasive and requiring waste disposal.

Pressure washing. Like dry ice blasting, pressure washing is non-abrasive and not harmful to the environment due to emissions or toxins. In contrast, this method is electrically conductive and requires wastewater disposal.

Solvents/chemicals. Cleaning with chemicals and solvents is another common non-abrasive cleaning method with no electrical conductivity issues. However, the process involves toxic substances and extensive waste removal efforts. These methods also pose risks to the environment.

Hand tools. Hand tools are environmentally safe, don’t use toxic materials, require no special waste considerations, and are not electrically conductive. Abrasiveness is a major drawback of hand tools, as are additional labor requirements.

Changes and advancements in the technology behind dry ice cleaning, this form of cleaning has become an increasingly practical and cost-effective alternative to traditional blast cleaning methods such as pressure washing, sandblasting, and chemical-based cleaning. Dry ice cleaning is faster and more effective leading to reduced downtime and cost. The process is also dry so that water or solvents don’t damage your equipment and is safe for electrical applications. This not only makes it environmentally safe but also doesn’t require any waste cleanup.

Contact us at The Blasting Lab today for more information on how we can reduce your down-time and cleaning costs.

Learn more about dry ice cleaning and get information on its approval by the EPA, FDA, and USDA.

TheBlastingLab.com © 2026 - All rights reserved | Website by: Sterr Bros